Custom Cable Assemblies

Description:

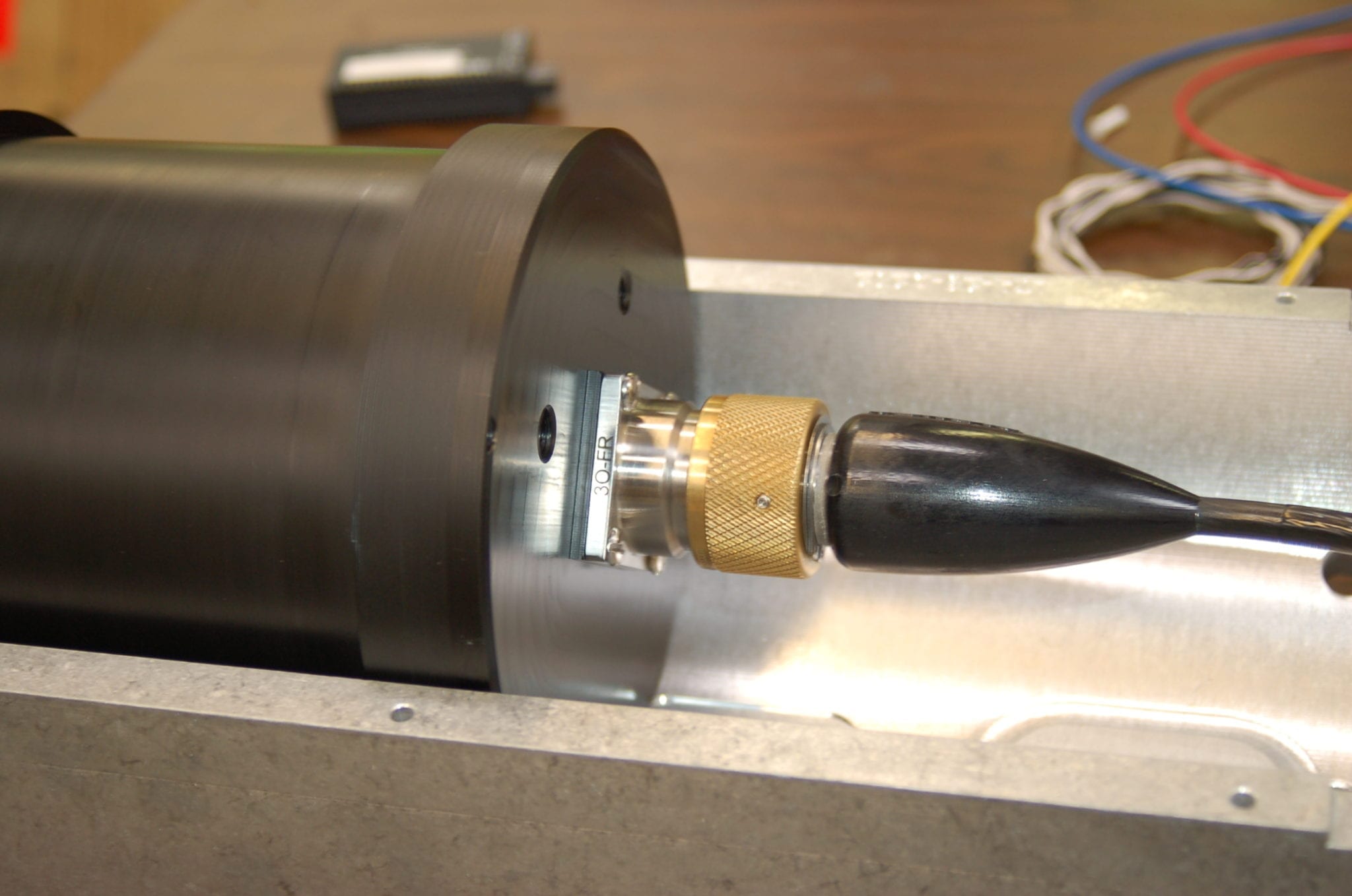

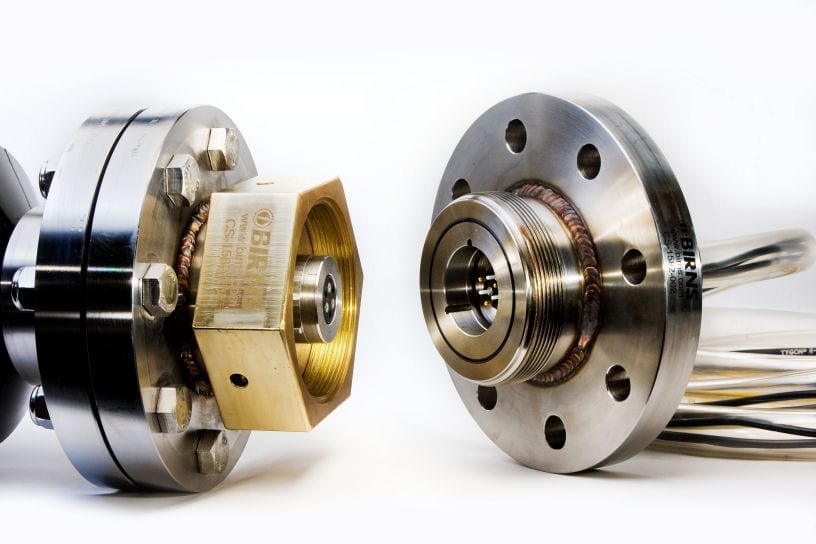

BIRNS custom-designs and manufactures connectors from nearly any material, performs oil-filled cable assembly, splices and breakouts, and molding of epoxy, polyurethane, neoprene and other materials in our NAVSEA S9320-AM-PRO-020 certified facility.

We perform hydrostatic pressure testing (to 20,000 PSI) electrical testing (to10kV), helium leak testing, triple optical testing, and in-house mechanical straight or side pull testing to 16,000 pounds.

Design Options

Custom Cable Assemblies Can Incorporate Any Combination of:

ELECTRICAL

High density (186 ways), high-voltage (=4.0kV/conductor), complex wiring (TSP, TST, TSQ) and coaxial cable. BIRNS electrical technicians and inspectors are certified IPC Specialists per J-STD-001 Class 3, and work is performed per IPC-A-610C.

FIBER-OPTICS

Single-mode or multi-mode optical fibers: <1.0dB MM loss @850nm, 1300nm; <1.0dB SM loss @1310nm, 1550nm; Typical per-contact loss <0.5dB (Testing per ANSI/TIA/EIA-455). BIRNS optical technicans are ETA-I certified.

MECHANICAL

BIRNS performs mechanical termination of load-bearing cables with central or coaxial stress members of Aramid fiber or steel; no load is transmitted to electrical conductors or optical fibers.

Additional Product Information:

Technical Data

Click on the following document links to view or download:

Support Materials

Click on the following document links to view or download: