BIRNS' Company History

BIRNS’ Milestones & Achievements

1954 BIRNS is established in Los Angeles, California.

1957 BIRNS makes the first professional underwater camera housings with 400-foot magazines, for the US Navy, to film tests of the secret Polaris underwater missile ejection system – films personally reviewed by President Eisenhower. For subsequent tests, BIRNS develops underwater lights to withstand the rocket’s engine blast and flame.

1963 BIRNS builds specialty lights for the US Man-In-The-Sea program. Subsequently, BIRNS makes lights for Sea Lab I, Sea Lab II, and the aborted Sea Lab III.

1968 BIRNS receives the largest contract for underwater lighting that the US Navy had ever awarded. Besides the US Navy’s Pacific and Atlantic Fleets, BIRNS is today proud to have supplied lights for the navies of Canada, the United Kingdom, Israel, Chile, Sri Lanka, and Brazil.

1971 BIRNS begins to design and produce lights for the growing offshore oil and deep-sea exploration industry. These lights need to withstand ever-increasing depths, and in 1973 BIRNS develops the BIRNS DEEPIE, tested to an equivalent depth of 42,000 FSW (13 km).

1979 BIRNS develops the self-contained underwater Magnetic Particle Inspection system, allowing a single diver to detect oil leaks and cracks or weld defects in underwater steel structures. In 1980, divers using the BLACKBIRN save the US Navy $180,000 in dry-docking costs on a single job. Today, BIRNS is the world’s primary supplier of underwater MPI and oil-detection systems.

1979 BIRNS develops the self-contained underwater Magnetic Particle Inspection system, allowing a single diver to detect oil leaks and cracks or weld defects in underwater steel structures. In 1980, divers using the BLACKBIRN save the US Navy $180,000 in dry-docking costs on a single job. Today, BIRNS is the world’s primary supplier of underwater MPI and oil-detection systems.

1980 The BIRNS Nuclear Lighting Division is founded to serve BIRNS’ rapid expansion into that field. Specialty products built for the nuclear industry include the Needle Light (a 500-watt light that fits inside 0.5″ (12.5 mm) holes), and a lighting system for GE’s AZTECH mobile low-level waste processing unit. Today, BIRNS lights are used by over 83% of the nuclear power stations in the USA; 54% of those in Western Europe; 75% of those in the Benelux countries; 50% of those in Scandinavia, and 25% of those in the Far East.

1985 The oldest shipwreck ever found (approximately 3,500 years old) is excavated using BIRNS lights. Among other underwater archaeological finds illuminated by BIRNS lights are the Civil War Ironclad “Monitor”, the “Hamilton”, the “Scourge”, the “Andrea Doria”, and the “Titanic”.

1987 Need for additional factory and office space prompts the move to Oxnard, California.

1988 After years of frustration trying to obtain consistently reliable connectors from existing manufacturers, BIRNS begins to manufacture underwater connectors for use with BIRNS popular lighting systems.

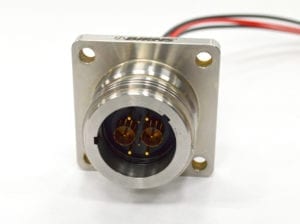

1990 The BIRNS Connector Division is founded in response to increasing customer demand for high-quality underwater connectors, which leads to the development of several full ranges of high-performance connectors, penetrators, and custom cable assemblies.

1991 A major manufacturer of marine geophysical equipment standardizes on BIRNS electromechanical connectors for use on all their RU-30 multiplexed data acquisition streamers.

1993 BIRNS develops the world’s first deep-submergence 575w HMI light. This amazing system, on the cutting edge of underwater lighting technology, is made entirely of titanium and produces 49,000 lumens (85 lumens/watt) with color rendering index of 90+, color temperature of 5600 K, 120/240 VAC (or 190-300 VDC) operation, hot-restrike, 60-second tool-free relamping, universal burning position, TTL compatible On/Off control, and dimming to 50%.

1993 BIRNS develops the world’s first deep-submergence 575w HMI light. This amazing system, on the cutting edge of underwater lighting technology, is made entirely of titanium and produces 49,000 lumens (85 lumens/watt) with color rendering index of 90+, color temperature of 5600 K, 120/240 VAC (or 190-300 VDC) operation, hot-restrike, 60-second tool-free relamping, universal burning position, TTL compatible On/Off control, and dimming to 50%.

1994 BIRNS develops the world’s most advanced seismically-qualified, nuclear-grade emergency light, and supplies 1,300 units to Korea (along with 336 BIRNS Kelvin nuclear fuel pool lights).

1995 BIRNS’ Quality Assurance system is qualified to meet the requirements of ANSI/ASME NQA-2, “Quality Assurance Requirements for Nuclear Facility Applications.”

1996 A major manufacturer of deep-ocean work-class ROVs standardizes on BIRNS high-density miniature metal shell connectors throughout its high-power work-class ROV systems, including on all subordinate systems (E.g. the tether-management system, cameras, thrusters, lights, etc).

1997 A US Navy detachment begins a 3-year program to replace all other underwater connectors on their unmanned vehicles with BIRNS Millennium connectors.

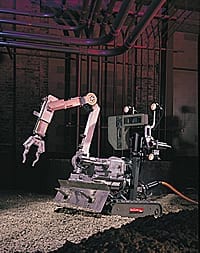

1998 BIRNS designs, builds and supplies a 186-conductor waterproof electromechanical cable assembly to withstand 3,000 pounds of load in any direction—in the high-radiation environment inside Chernobyl. RedZone Robotics commissioned BIRNS to design and build these complex connector systems for its Pioneer Robot—designed to go into Chernobyl’s Unit 4 sarcophagus, a 20-story, 300,000-ton concrete shell created over the plant as a containment effort.

1998 BIRNS designs, builds and supplies a 186-conductor waterproof electromechanical cable assembly to withstand 3,000 pounds of load in any direction—in the high-radiation environment inside Chernobyl. RedZone Robotics commissioned BIRNS to design and build these complex connector systems for its Pioneer Robot—designed to go into Chernobyl’s Unit 4 sarcophagus, a 20-story, 300,000-ton concrete shell created over the plant as a containment effort.

1999 The manufacturer of 85% of the world’s commercial diving helmets standardizes on BIRNS underwater connectors. Other users include a high-performance oceanographic instrumentation system integrator, a manufacturer of 6km advanced-technology ROVs, and a US Navy prime contractor.

2000 BIRNS develops an advanced unique double-ferrule electro-hydraulic connector adapter system for use with underwater electrical oil-filled cables, and supplies 5,000-volt oil-filled cable assemblies to a major US Navy prime contractor. The solution solved the risk of cut tubing with underwater oil-filled cables for deep submergence ROVs—to this day BIRNS is the only company offering this level of sophistication in oil-filled cable connector technology.

2000 BIRNS develops its DPT (Delamination Preclusion Technology), based on an effective NCC (Non-Conductive Coating) to obviate Cathodic Delamination. BIRNS supplies DPT-protected penetrators and cable assemblies for high-pressure manned submersibles, with testing witnessed by American Bureau of Shipping.

2001 BIRNS develops Class A 100-amp power connectors for deep-submergence manned submarines, to withstand high open-face pressure.

2001 BIRNS develops Class A 100-amp power connectors for deep-submergence manned submarines, to withstand high open-face pressure.

2001 BIRNS develops Class A high-performance 50Ω coaxial connectors, with polyethylene dielectrics, for use with GPS-frequency military submarine antennae, to withstand open face pressure to 2km depth.

2002 BIRNS develops expertise in molding Tefzel fluoropolymer and bonding it to stainless steel connectors and Tefzel-jacketed cables. BIRNS also perfects techniques for molding Hypalon (CSPE), further expanding BIRNS’ high-performance molding and bonding repertoire.

2002 BIRNS produces Titanium-shell single-pin Class A connectors, to withstand open face pressure to 10km depth.

2005 BIRNS Delivers Class A hybrid high voltage electro-optical cable assembly. This BIRNS Millennium 3T size assembly featured two multimode optical fibers, eight 2.5Kv conductors, and four 600v conductors. Triple multimode optical loss testing (at 850nm) of the mated assembly confirmed connector repeatability of <2dB. BIRNS was called upon to deliver the robust hybrid electro-optical cable assembly for the Naval Facilities Engineering Service Center (NAVFAC ESC) for a new Low Frequency Active Sonar (LFAS) system to be deployed from an 11m Rigid Inflatable Boat (RIB).

2005 BIRNS delivers cable assemblies to the University of Wisconsin’s Physical Sciences Laboratory for the IceCube Neutrino Project, to instrument 1 Km3 of ice at the South Pole. BIRNS supplied high-power Metal Shell connectors for IceCube’s submersible pumps, each with four 2 AWG contacts, in the MSSM shell size. BIRNS also supplied miniature instrumentation connectors for temperature and pressure sensors, in the BIRNS Millennium Series’ 3G shell size.

2005 BIRNS delivers cable assemblies to the University of Wisconsin’s Physical Sciences Laboratory for the IceCube Neutrino Project, to instrument 1 Km3 of ice at the South Pole. BIRNS supplied high-power Metal Shell connectors for IceCube’s submersible pumps, each with four 2 AWG contacts, in the MSSM shell size. BIRNS also supplied miniature instrumentation connectors for temperature and pressure sensors, in the BIRNS Millennium Series’ 3G shell size.

2008 BIRNS develops for Phoenix International a quick-disconnect high-voltage EOM (Electro-Opto-Mechanical) cable termination, with 3 single-mode fibers, 3 x 3.6Kv copper power lines, and 36,000 lb (16,400 Kg) mechanical strength member. Side-load capability tested to 7,000 lbs (3200 Kg).

2009 ABS (American Bureau of Shipping) witnessed a new, upgraded qualification test of BIRNS NPT penetrators (those beginning with P13N, P19N, and P25N) to 1,700 PSI. (Previous qualification test was 1,500 PSI.) Thus, BIRNS penetrators may now be used with working pressures of up to 680 PSI. (Qualification test pressures are 250% of maximum working pressure; “production” test pressures are 150% of maximum working pressure.) ABS reviewed and approved the BIRNS test procedure as conforming to its requirements.

2009 BIRNS’ Quality Management System is reviewed by Perry Johnson Registrars, Inc., and is certified to conform to the requirements of ISO 9001:2008. This certification applies to BIRNS’s design and manufacture of Underwater, In-Air and Emergency Lighting Systems and Electro-opto-mechanical Connectors, Penetrators and Cable Assemblies for Nuclear, Deep Submergence/Marine and Diving Decompression Use.

2010 BIRNS launches a new state-of-the-art hyperbaric testing program for ABS-approved penetrators and connectors—a custom-designed hydrostatic pressure test system with a range of vessels rated to 20,000, 10,000, 5,000 and 1,000 psi. The company becomes the only one in the industry able to provide inclusive pricing and lead times for ABS/DNV certification. BIRNS has also added a new high volume helium testing capability, exceeding stringent ABS requirements for man-rated penetrator testing.

2010 BIRNS introduces a new line of standardized, affordable electro-optical hybrid connectors as a supplement to its wide range of custom connector lines, including the standard hybrid BIRNS Millennium™ 3T series (also capable of handling high voltage (≤ 3.6Kv) conductors), in which users can specify up to 31 electrical wires and up to 10 optical fibers, and the standard hybrid BIRNS Millennium™ 3O, with a single optical fiber and up to 10 electrical wires, allowing unparalleled versatile high performance connectivity.

2010 BIRNS expands its popular lines of commercial diving and subsea lighting products to include new, innovative LED options in the versatile BIRNS “L” series—chamber lights and helmet and ROV work lights—all with 50,000 hour lamp lives and brilliant LED illumination.

2011 BIRNS receives American Bureau of Shipping (ABS) Product Design Assessment (PDA) Certification for its tremendously popular lines of penetrators. This certification process included rigorous testing and review by the national organization, and results in ABS pre-approving all design, drawing and test procedures for BIRNS electrical penetrators and cable assemblies for underwater vehicles, systems and hyperbaric facilities for use on a variety of ABS-class vessels.

2011 BIRNS receives American Bureau of Shipping (ABS) Product Design Assessment (PDA) Certification for its tremendously popular lines of penetrators. This certification process included rigorous testing and review by the national organization, and results in ABS pre-approving all design, drawing and test procedures for BIRNS electrical penetrators and cable assemblies for underwater vehicles, systems and hyperbaric facilities for use on a variety of ABS-class vessels.

2011 BIRNS’ Quality Management System is certified to the requirements of ISO 9001:2008 by Det Norske Veritas (DNV). The company’s Quality System also complies to the requirements of NRC 10CFR50, Appendix B- “Quality Assurance Criteria For Nuclear Power Plants and Fuel Reprocessing Plants”.

2011 The BIRNS logo receives a registered trademark from the United States Trademark and Patent Office (USPTO).

2012 BIRNS’ world-class molding facility is now NAVSEA S9320-AM-PRO-020 certified, and is one of only seven such commercial organizations in the country.

2013 Both the BIRNS Corona™ and the BIRNS ELF-LED™ are seismically qualified and even exceeded the rigorous IEEE-344 requirements during a brutal test. They both successfully passed at ≈ 8 gs of spectral acceleration at key frequencies−proving them capable of surviving the strongest of earthquakes.

2014 BIRNS celebrates a major milestone: its 60th year in business.

2014 BIRNS celebrates a major milestone: its 60th year in business.

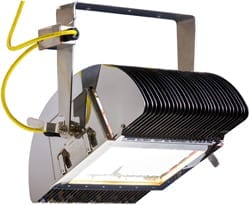

2014 BIRNS provides a quantum leap forward for high bay lighting inside containment with the BIRNS Quantum™ floodlight. This groundbreaking new system delivers powerful, extended use LED illumination for demanding high ceiling applications with a 21,383 lumen output with a 109,000 hour lamp life. It provides safer, more comfortable and efficient working conditions in the reactor building with a near- daylight color temperature of ~5000K. With a low 210W power draw, along with optical efficiency of nearly 83%—102 lumens per Watt—it offers huge energy savings over metal halide and tungsten-halogen lamp options.

daylight color temperature of ~5000K. With a low 210W power draw, along with optical efficiency of nearly 83%—102 lumens per Watt—it offers huge energy savings over metal halide and tungsten-halogen lamp options.

2015 BIRNS launches a new range of coaxial subsea connector contacts with unheard of performance characteristics, including a maximum insertion loss of 0.7 dB at signal frequencies to 3GHz, with an associated maximum SWR (Standing Wave Ratio) of 1.7:1. Even more remarkable, the new coax contacts withstand open face hydrostatic pressure to depths of 1433m in initial testing.

2015 BIRNS launches a new range of coaxial subsea connector contacts with unheard of performance characteristics, including a maximum insertion loss of 0.7 dB at signal frequencies to 3GHz, with an associated maximum SWR (Standing Wave Ratio) of 1.7:1. Even more remarkable, the new coax contacts withstand open face hydrostatic pressure to depths of 1433m in initial testing.

2018 BIRNS’ Quality Management System receives acclaimed ISO 9001:2015 certification from DNV-GL.

2020 BIRNS team developed exclusive deep submergence cable constructed for Cat 8.2 use, and deep submergence cable assemblies with data transfer rates of 9.4+/- 0.1 Gigabits per second. Performance testing proved that data consistently transmitted at this rate over the entire range of pressures from 0 to 8700 PSI/600 bar (6000m equivalent depth).

2020 BIRNS team developed exclusive deep submergence cable constructed for Cat 8.2 use, and deep submergence cable assemblies with data transfer rates of 9.4+/- 0.1 Gigabits per second. Performance testing proved that data consistently transmitted at this rate over the entire range of pressures from 0 to 8700 PSI/600 bar (6000m equivalent depth).

2021 BIRNS introduces the BIRNS Lumena-6™–a remarkable LED nuclear floodlight with an 85,000 lumen output, more than 61,000 hour lamp life and certified for use in water to 70°C without life reduction. This seismically qualified lighting system features an exclusive integrated onboard water cooled electronics enclosure, so a single mains power cable is all that’s needed on the surface.

2021 BIRNS introduces the BIRNS Lumena-6™–a remarkable LED nuclear floodlight with an 85,000 lumen output, more than 61,000 hour lamp life and certified for use in water to 70°C without life reduction. This seismically qualified lighting system features an exclusive integrated onboard water cooled electronics enclosure, so a single mains power cable is all that’s needed on the surface.

2024 BIRNS introduces groundbreaking coax capabilities: 6,000M open face rated RF cable assemblies.