Home / Marine / Connectors & Cable Assemblies / BIRNS Millennium Series

BIRNS Meridian™ Underwater & Deepsea

Interconnect Products

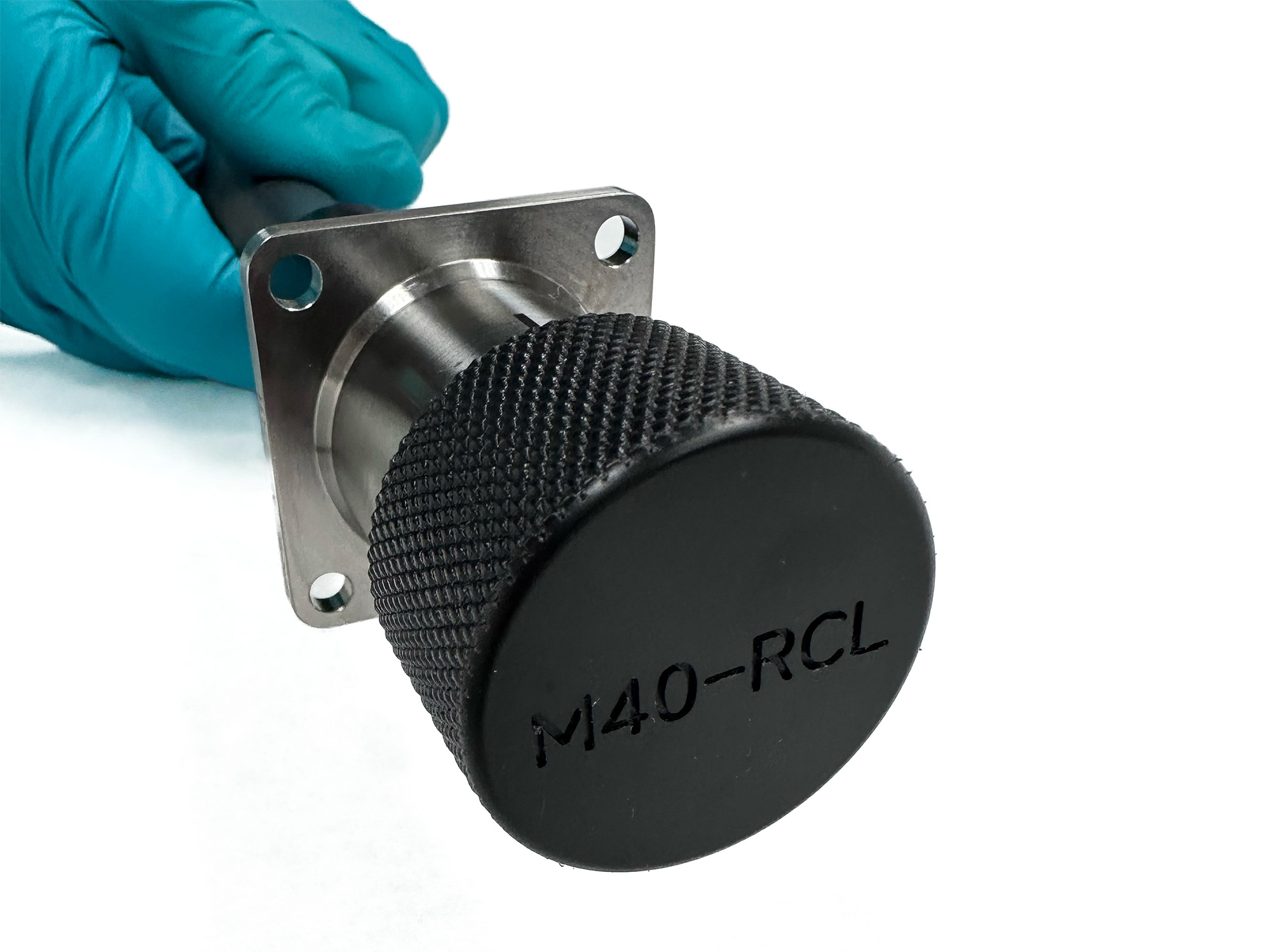

BIRNS Meridian M40-1 Titanium Connector Pair

POWER & PERFORMANCE

The BIRNS Meridian™ series is a dry-mate high amperage subsea connector line. This robust, custom engineered 225 Amp series is open face rated to 6km, and is perfect for battery packs and thrusters for crewed and uncrewed subsea vehicles that require high amperage power transfer. Select sizes are already being DNV type-approved for 6km rated crewed submersibles. BIRNS Meridian connectors are compact, and feature several pin configurations, with more in design for release. The M40 pin configuration has a single 85 mm2 (3/0 AWG) contact. Both standard and reverse gender versions are featured in the series, and all withstand reverse pressure, too, and can be installed into both dry and oil-filled canisters.

The Meridian connector line has a number of exclusive design features to create ease of use and mating, including a tactile alignment index ridge and arrows indicating the primary key position. The receptacles also feature a blue color band on the shell, which allows users to have a strong visual indicator that a connector pair has been fully mated.

BIRNS Meridian™ Overview

BIRNS Meridian™ Interconnect

Interconnect Series

DEEPSEA POWER CONNECTORS

The BIRNS Meridian series is a high performance, high current dry-mate interconnect range suitable for deep submergence applications to 6km depth. This series is available in straight or 90° configurations and offers standard and reverse-gender options. Configurations are open-face rated to 6,000 meters and select sizes are DNV Type-Approved for 6,000 meter rated crewed submersibles.

BIRNS Meridian cable assemblies provide quantifiably superior performance characteristics: better electrical transfer and greater safety, greater depth capability, and lower insertion and transfer losses. This has been achieved through meticulous and innovative engineering and rigorous testing, and includes a range of industry-leading design features described in detail in the rest of this section. The result is a powerful, robust subsea connector series providing the highest performance field-proven interconnect solutions on the market.

CABLE PLUGS

RECEPTACLES

OVERMOLD CONNECTORS

PRESSURE CAPS

DUMMY SEALING PLUGS

DUMMY SEALING RECEPTACLES

BIRNS Meridian™ Interconnect

ELECTRICAL PERFORMANCE

UNDERWATER CONNECTOR POWER

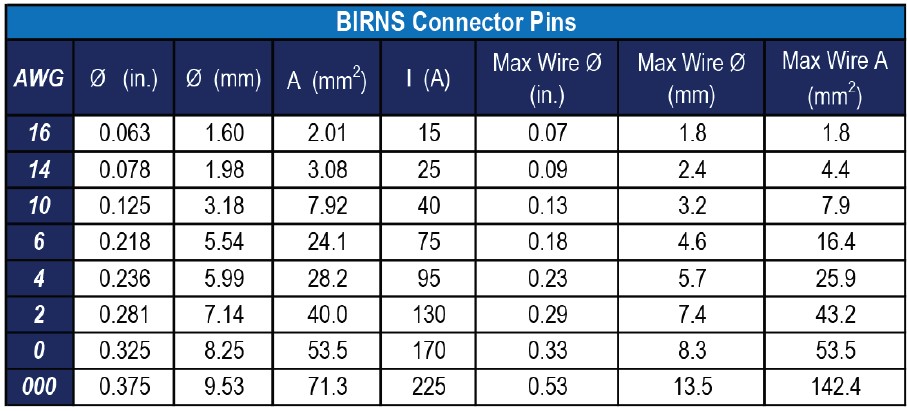

BIRNS Meridian electrical interconnect products are ideal for high performance subsea systems requiring outstanding power transfer. They provide excellent contact engagement per MIL-STD-39029D, with insulated solder pots to minimize EMI. Sockets are heat-treated BeCu for longevity and superior electrical contact, and all contacts are plated per QQ-S-365 or MIL-G-45204 for longevity.

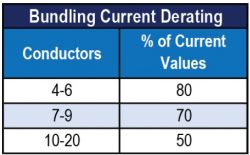

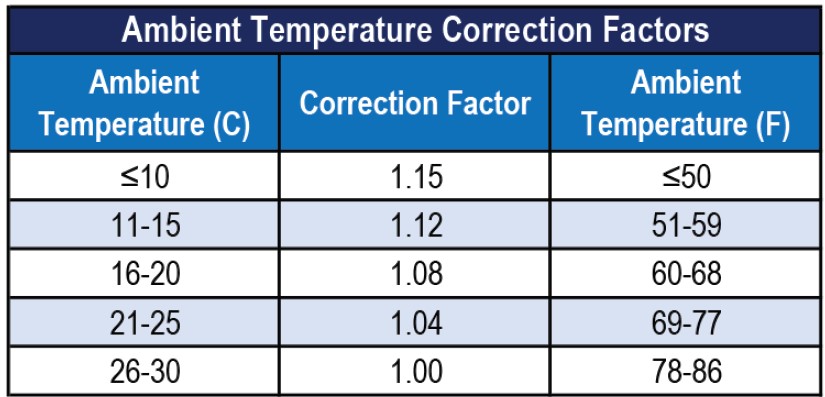

Actual measurements of AWG sizes can vary from manufacturer to manufacturer. BIRNS conductors are larger than standard AWG sizes to provide additional safety and flexibility.

BIRNS ampacity values are merely informational. The system’s electrical designers are responsible to perform detailed engineering analyses of the many factors affecting ampacity.

1. National Fire Protection Association 70, National Electric Code.

2. Assumes use of 90°C-rated insulation.

BIRNS Meridian™ Interconnect

MECHANICAL PERFORMANCE

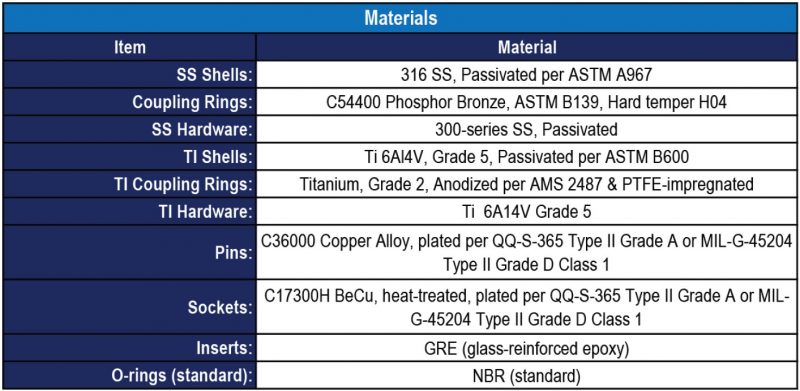

UNDERWATER CONNECTOR MATERIALS

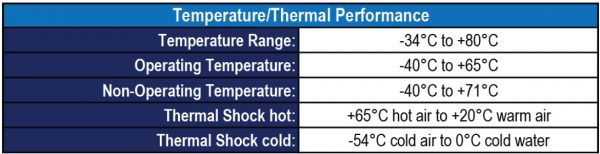

TEMPERATURE/THERMAL PERFORMANCE

The listed Temperature Range is based on engineering analysis of materials. The Operating and Non-Operating Temperatures and the Thermal Shock (hot and cold) data are derived by extension from actual testing performed on BIRNS Millennium connectors. Please contact the BIRNS Technical Sales Team for more information.

1. Actual testing was performed to 1,212 bar, equivalent to a simulated depth of 12,000 meters. This is 10% deeper than the very deepest part of the seabed.

2. Galling is adhesive wear, particularly in high-ductility metals, caused by transfer of material between surfaces during transverse motion. Per ASTM G40: “Galling is a form of surface damage arising between sliding solids, distinguished by microscopic, usually localized, roughening and creation of protrusions (e.g., lumps) above the original surface”.