BIRNS Millennium 3O-9HV Plugs

CP Type Cable Plug; Stainless & Ph. Bronze

SELECT CABLE PLUG OPTIONS:

$847.00 – $2,068.00Price range: $847.00 through $2,068.00

- Add 3O-9HV Compatible Products

About 3O-9HV Cable Plug Inserts

- Electrical Circuits:

- RF Circuits:

- Optical Circuits:

- Notes:

- 10 AWG HV (8mm2) - 5 Wires - 40A

- 20 AWG (.8mm2) - 4 Wires - 6A

- - -

- - -

- - -

- - -

- HV: ≤ 3.6 kV

Shell-Insert Pin Configuration & Wiring Worksheet:

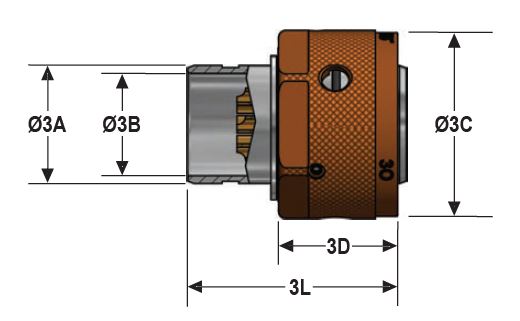

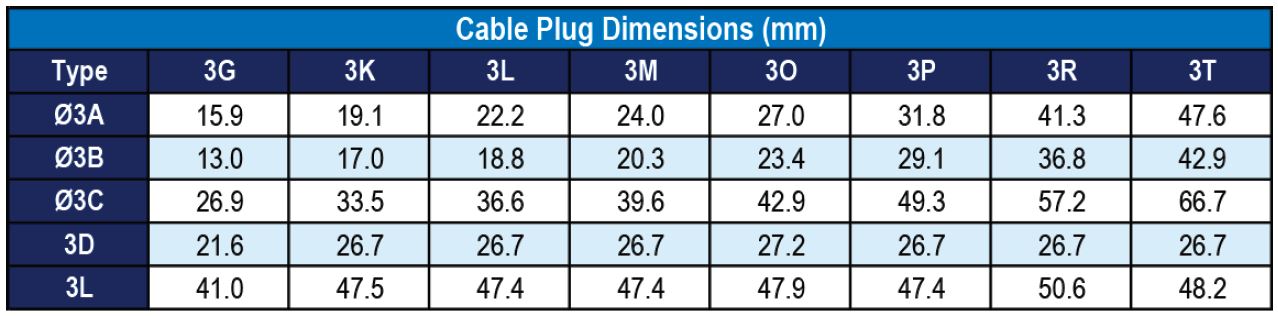

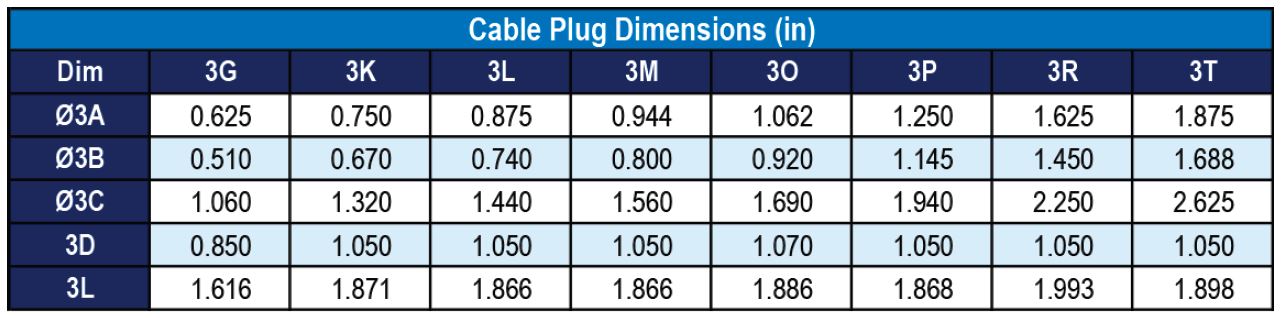

Cable Plug Dimensions

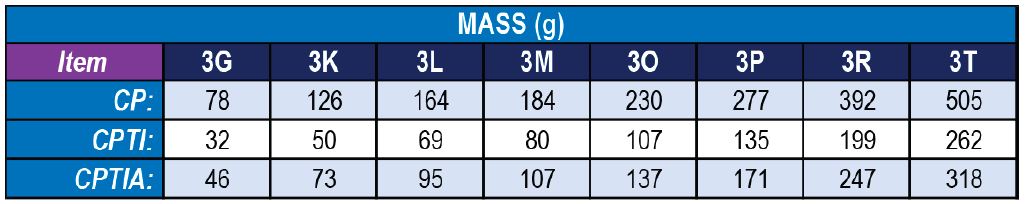

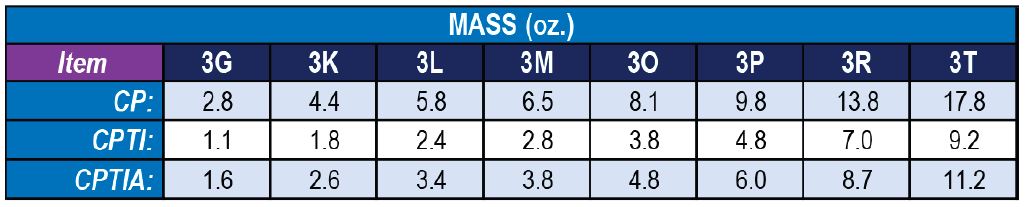

Cable Plug Mass

Mass

BIRNS Millennium Cable Plug masses are detailed in the following tables. These figures do not include the mass of any cable or wire, solder, insulating tubing, or potting or overmolding materials. Due to the different insert masses as a result of various contact quantities and sizes, these mass figures include a representative insert.

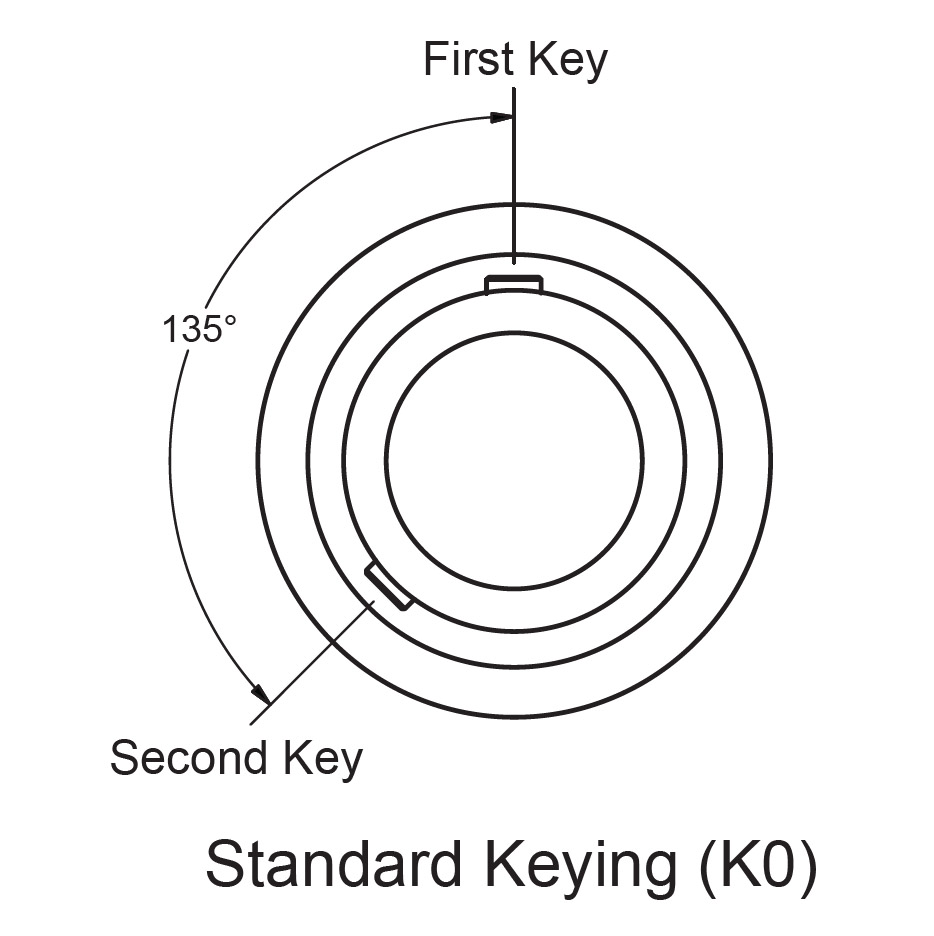

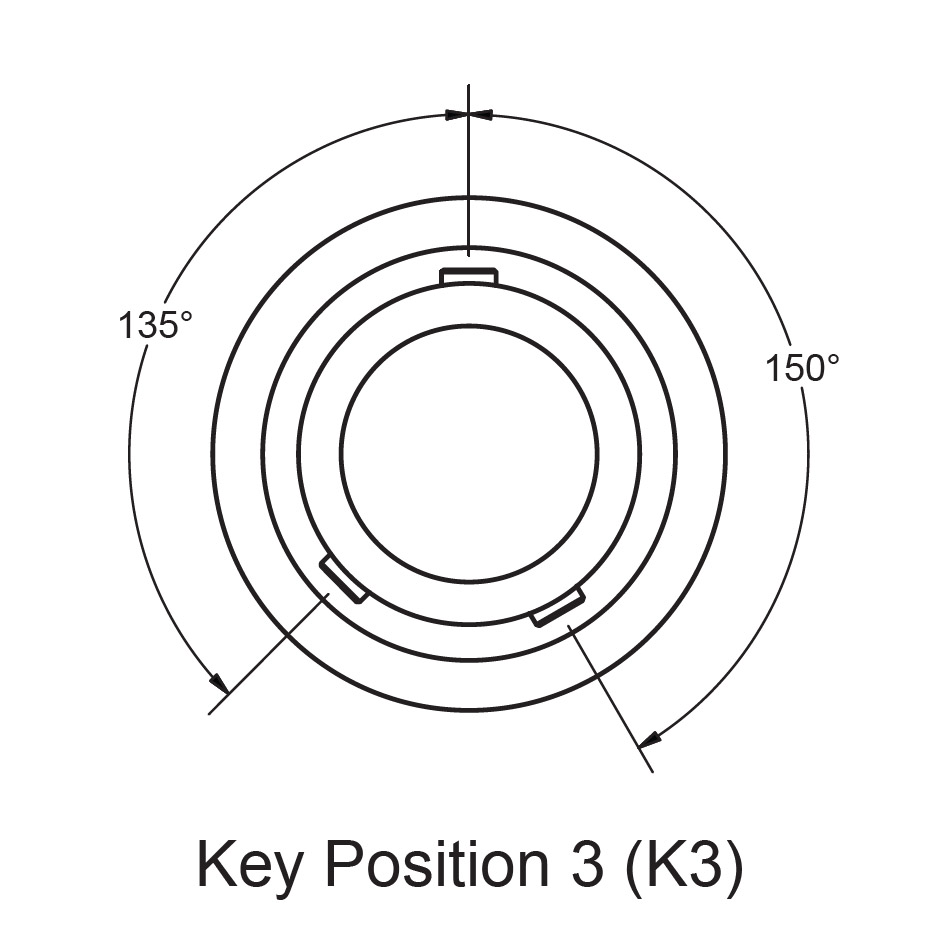

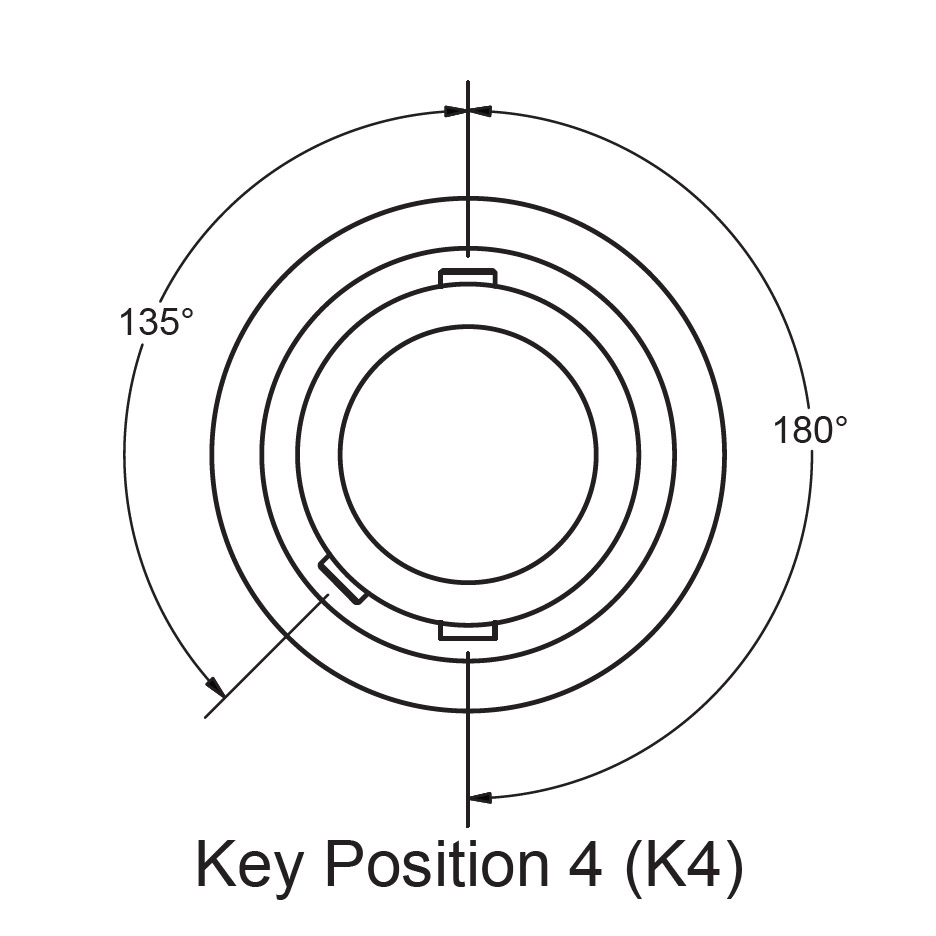

Cable Plug Key Positions

Key Options

As the BIRNS Millennium series is specifically engineered for challenging signal and power applications, keys for the series precisely and accurately orient connector mating and maintain that accuracy over the system’s lifetime, while providing ease of use under harsh conditions. To that end, keys are machined as seamless integral elements of the connector shell*, of the same block of metal, with squared silhouettes for maximum strength, durability, and secure mating process.

For the ultimate in precision indexing, BIRNS Millennium connectors have dual keys and keyways. Users also have the option of a third key, providing purposeful incompatibility, when needed, to preclude inadvertent misconnection in the field. The optional third key can be specified in one of three positions, designated by part number suffixes K2, K3, or K4.

*Lesser-quality connectors use cheap press-fit keys.

Pro Tip: CPs with standard keys (K0) universally fit ALL receptacles (K0, K2, K3, K4). For suitable compatibility, always ensure that the CPs have the appropriate key options (K2, K3, K4).

Cable Plug Quality Management

Connector Serialization

In accordance with its comprehensive Quality Management System, BIRNS individually and permanently serializes all connector shells, allowing quality traceability back to the shell’s original manufacturing material certificates and dimensional

inspection reports. Serialization marking is performed by means of laser etching.