BIRNS Millennium 3P-13 Oil-Filled Connectors

BIRNS Oil-Filled Connectors

VERIFY

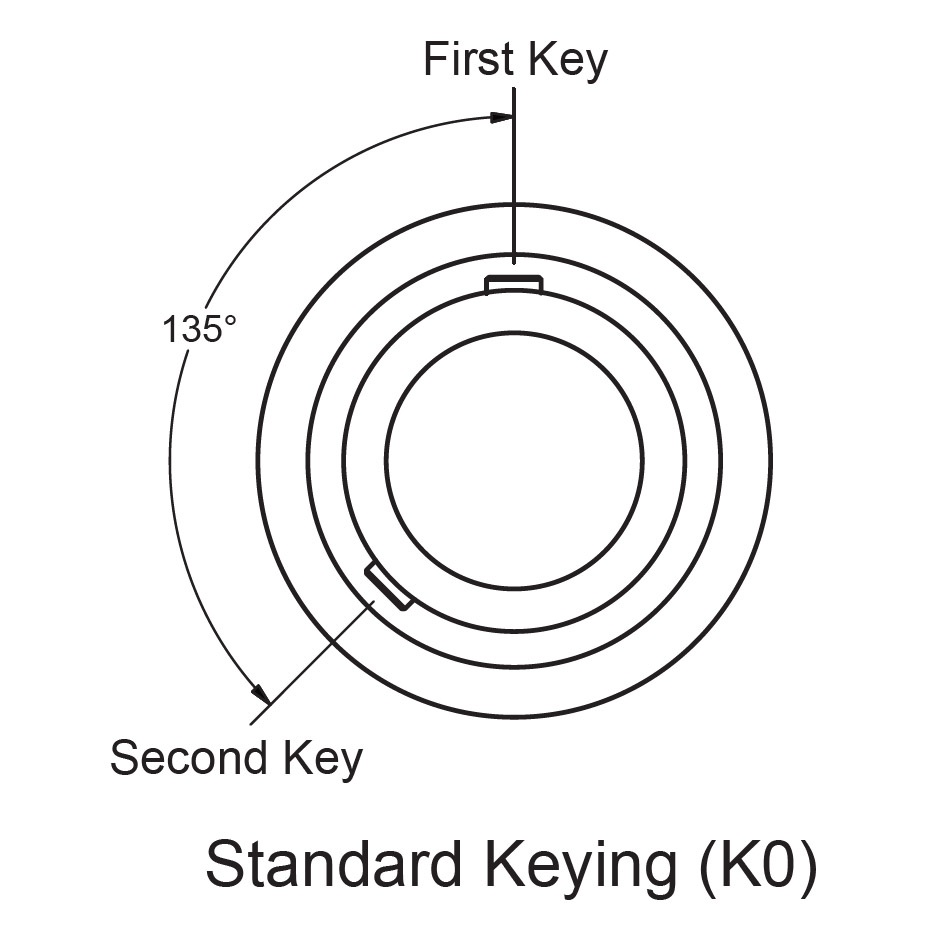

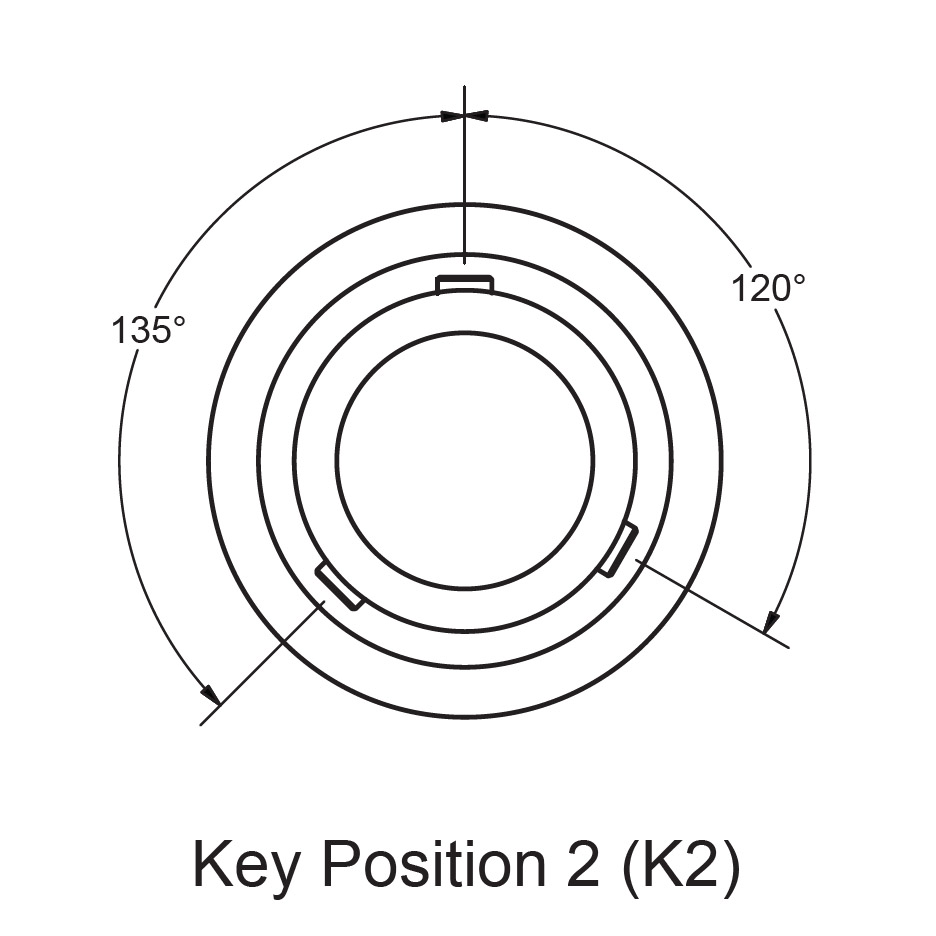

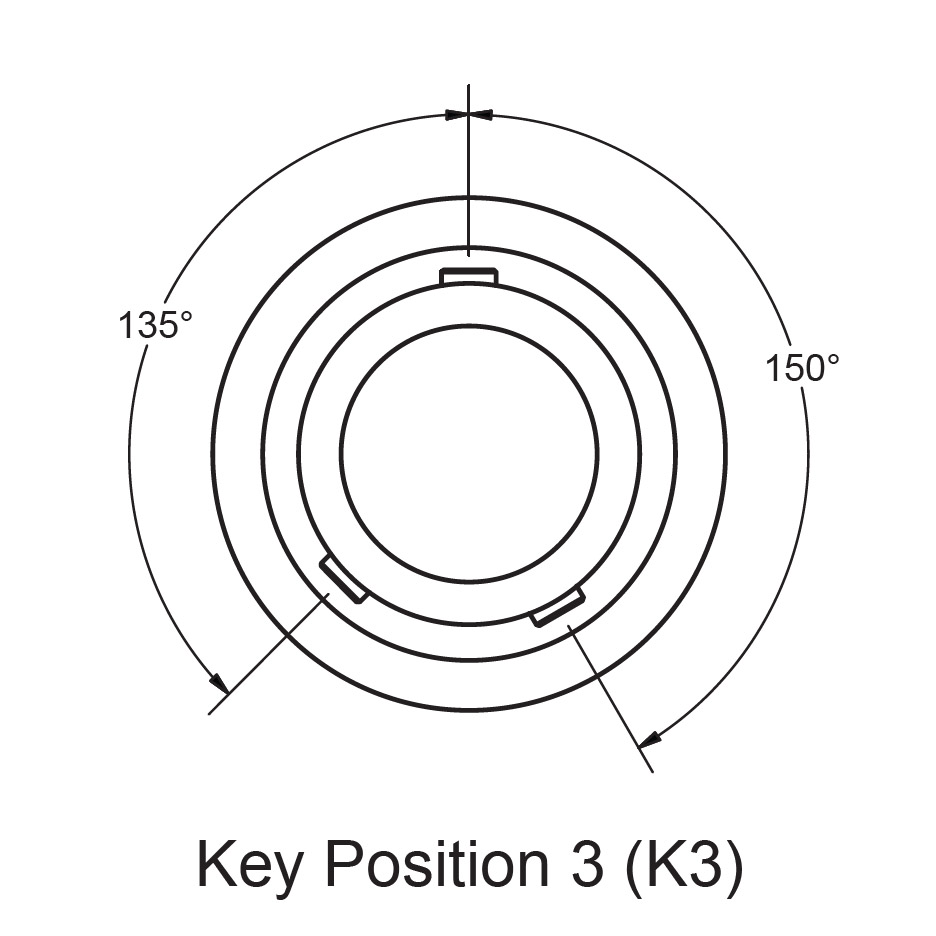

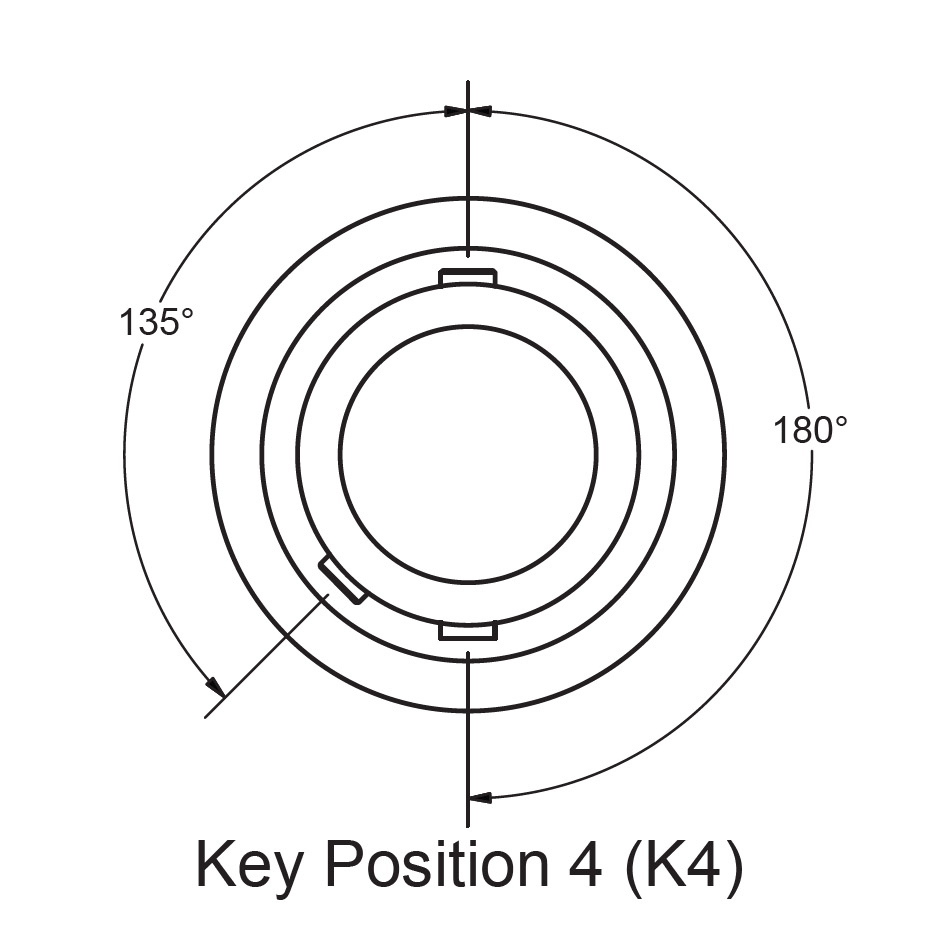

KEY MATING

Plug & Receptacle must match to assure correct connector mating.

SELECT CONNECTOR OPTIONS:

$1,424.00 – $2,864.00Price range: $1,424.00 through $2,864.00

Product Specifications

Millennium 3P-13

-

Oil-Filled Connector

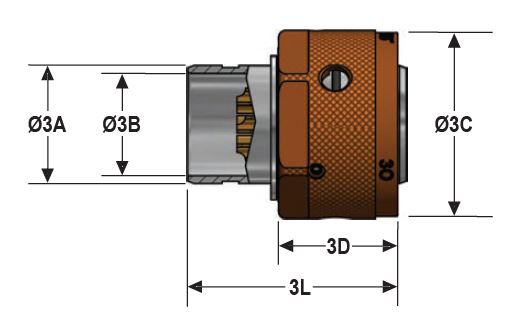

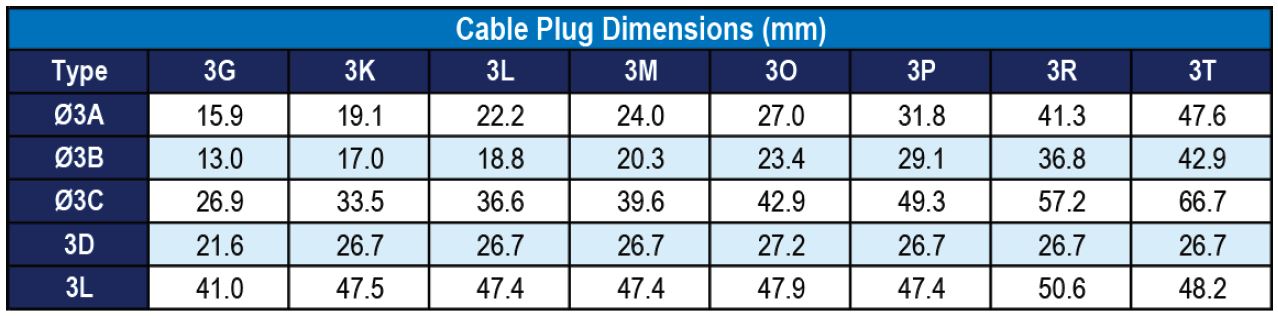

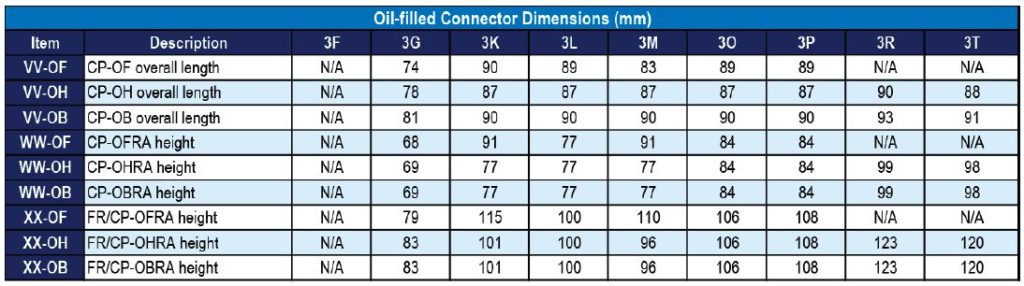

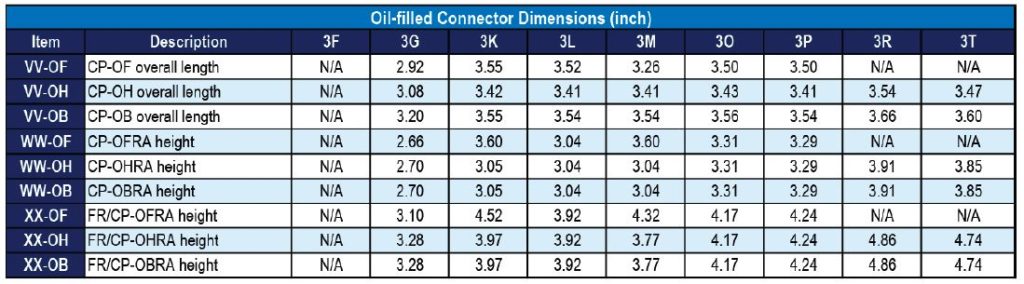

Dimensions & Clearances

Review Oil-Filled Connector Hose & Backshell Dimensions & Clearances

For additional information, please download the complete catalog above.

- Add 3P-13 Compatible Products

3P-13 Cable Plug Insert Circuitry

- Electrical Circuits

- RF Circuits

- Optical Circuits

- Notes:

- 10 AWG (8mm2) - 13 Wires - 40A

- - -

- - -

- - -

- - -

- - -

- - -

Shell-Insert Pin Configuration & Wiring Worksheet:

Cable Plug Materials

Materials: Shell Material | Shell Hardware | Coupling Ring

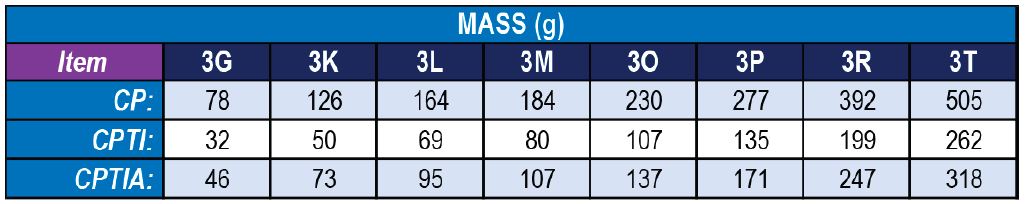

Cable Plug Dimensions & Mass

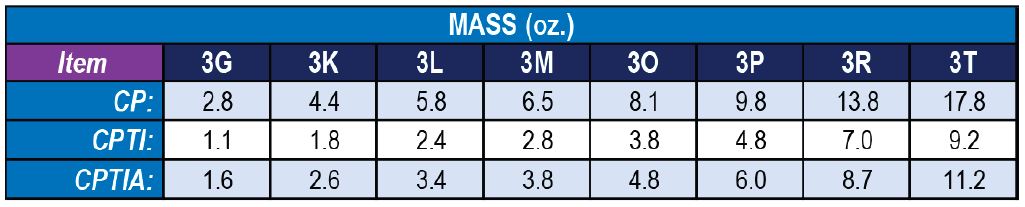

BIRNS Millennium Cable Plugs are dimensionally equivalent irrespective of different materials and/or Key Options. Masses detailed in the following tables do not include the mass of any cable or wire, solder, insulating tubing, or potting or overmolding materials. Due to the different insert masses as a result of various contact quantities and sizes, these mass figures include a representative insert.

Backshell Designs & Materials

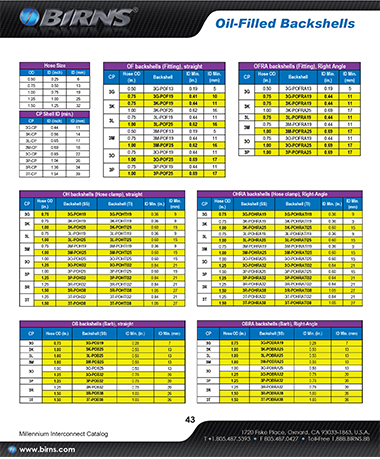

Oil-filled cable assemblies constitute conductive lines inside a hose containing an inert fluid. For some applications, oil-filled cable assemblies provide significant advantages: design flexibility, in-field serviceability, and inherent pressure balancing. However, successful use of oil-filled assemblies requires special consideration of design elements, for example that all conductors used in oil-filled cable assemblies must be sheathed or insulated with materials, such as PTFE, which withstand long-term oil immersion.

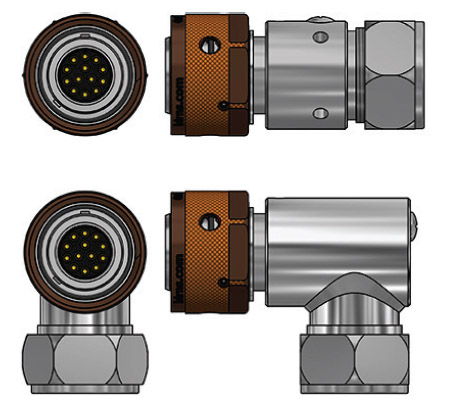

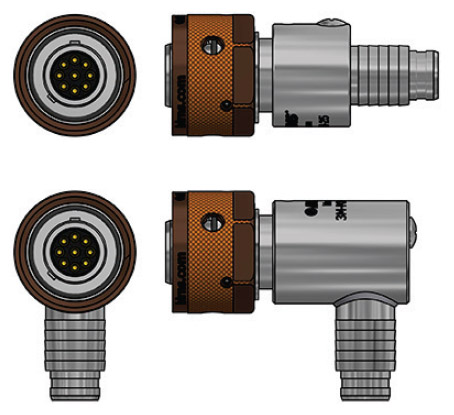

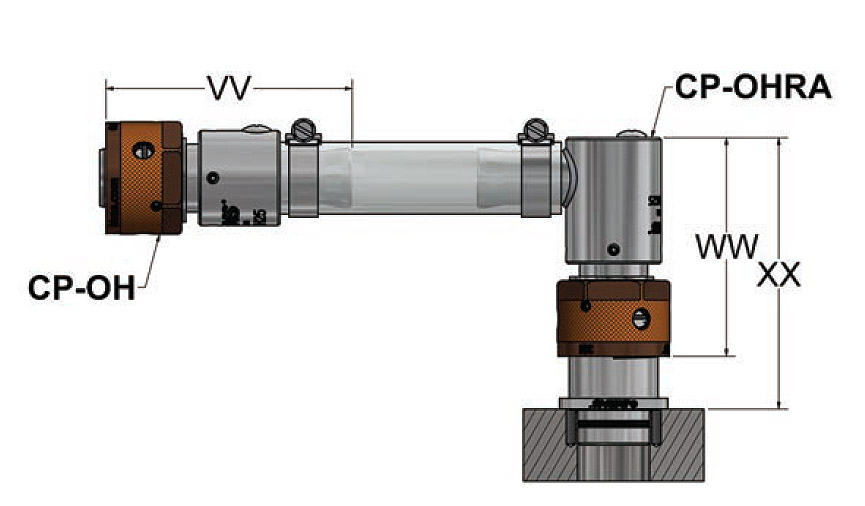

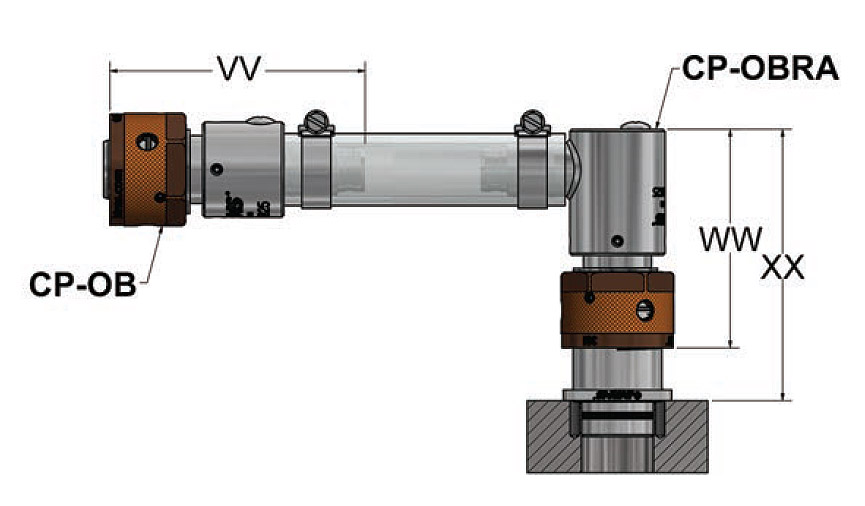

BIRNS Millennium connectors can be used in oil-filled cable assemblies1 with a backshell (adapter) to affix the hose to the connector. Select types are available for multiple hose sizes. We offer three backshell designs: OF: swaged hydraulic Fitting (accepts overall braided shield), OH: Hose clamp, OB: Barb stem (accepts overall braided shield)

NOTES:

1. When used with oil-filled cable assemblies, connectors may require special sealing caps. See Caps (Page 37 – BIRNS Millennium Interconnect Catalog Rev E-1) for details.

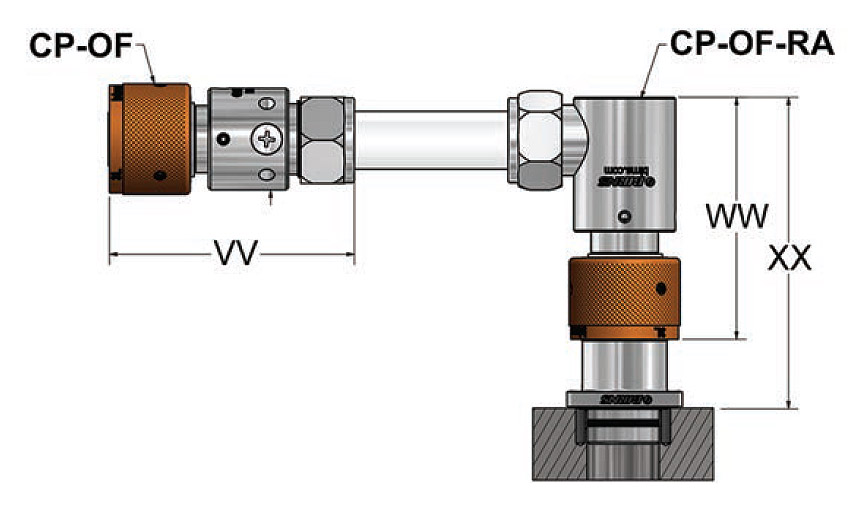

It’s important to ensure sufficient internal clearance for the wire bundle. First ascertain the maximum diameter of the wire bundle. Then, select a hose size with sufficient ID. (See the “Hose Size” table on the next page.) Finally, verify that the backshell, too, has enough internal clearance.

Pro Tip: remember to include any braided OAS in the wire-bundle diameter.

Each backshell style has unique internal geometry and wire clearance. The minimum clearance ID is listed for each backshell in the tables on the next page. When multiple hose size backshells are available for any CP shell size, the recommended size is highlighted in yellow: it is larger and thus provides greater internal wire clearance.

Pro Tip: use the backshell minimum ID to verify sufficient wire-bundle clearance. This ID will often be the constraint throughout the cable assembly.